● Flow rate: 500-1900m3/hr

● Head H(m): 10-80m

● Speed: 300-650rpm

● Efficiency: Max. 80%

● Materials: Impeller – High Chrome Alloy A05

Inner Liners: Soft Black Rubber R55

● Impeller: 5-Vane Closed Type

● Vane Diameter(mm): 762

● Solids Passing(mm): 86

● Power: Max 560Kw

● Color: RAL5002

● Weight: 3500KG

● NPSH (m): 2-8

● Warranty: 1 year Warranty (except wet-end parts)

Introduction:

The advantages of SH/250ST rubber slurry pump with metal impeller:

1. Anti-corrosive rubber liner has features of a wide range of performance, high efficiency, and high-performance cost ratio.

2. Rubber liner is light, thus easy to install and maintain.

3. As the name suggests, the anti-corrosive rubber liner is made of rubber which is of high elasticity and chemical stability. The rubber also absorbs noise and vibration, which is more anti-corrosive than high chromium alloy.

4. Some metallurgy design and research institutes and universities of science and technology provide lots of technological supports. Thus, our rubber discharge end is trustworthy and effective.

5. A series of quality tests are carried out when a rubber liner is being used.

6. Metal impeller is more abrasion and erosion resistant, which will extend the pump’s service life, and guarantee the discharge head of the pump.

Specifications:

| Pump Model | SH/250ST (12”×10”) |

| Outlet | 10-inch |

| Capacity | 500-1900m3/h |

| TDH | 10-80m |

| Rated Motor Power | 560Kw |

| Speed | 300-650rpm |

| NPSH | 2-8m |

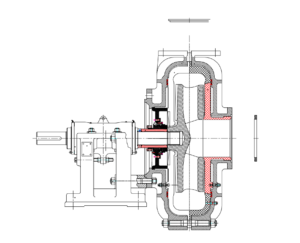

Construction of Rubber Slurry Pump with Metal Impeller:

Typical Applications:

Tailings

Heavy Mining

Ash Handling

Cyclone Feeds

Pulp and Paper

Corrosive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Heavy Refusal Removal

SME SHR Slurry pumps are designed for the corrosive slurry applications